Dehumidification for lithium ion battery production

Production of lithium ion batteries requires extremely low humidity conditions. Lithium reacts with water vapour and inaccurate humidity control in a battery production area can have severe consequences, as well as leading to a drop in product quality.

Due to the extreme requirement for moisture control, the energy required for this part of the manufacturing process is significant and therefore has a substantial impact on the profitabilty of any battery manufacturing operation.

Condair offers desiccant dehumidifier technology with energy saving features that make it ideal for battery cleanroom applications. The flexible design of Condair desiccant dehumidifiers allows the energy needed for regeneration to be taken from heat recovery systems, hot water, steam, gas or electric sources.

Condair's design team will work with a battery manufacturer to ensure that the proposed drying solution meets the required manufacturing conditions, as well as any energy consumption goals.

Our local sales and service teams can provide engineering support to clients wherever they are, whilst Condair's global design capability offers world-leading expertise for cutting edge manufacturing solutions.

Condair dehumidifiers for lithium ion battery production offer:

- Multi-rotor designs to meet practically any humidity requirement

- Low energy systems with heat recovery and hot water heating options

- Global design expertise to provide customized drying solutions

- Local engineering support for reliable operation in critical environments

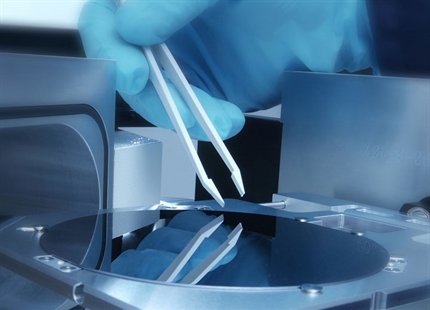

Condair DA desiccant dehumidifier

Talk to an expert in battery manufacturing drying solutions

PODCAST: HOW TO SIZE & SELECT A DEHUMLearn the important things to consider when approaching a commercial dehumidifier project.

Free 10-point guide to specifying dehumidifiers

Download your free 10-point guide to specifying dehumidifiers and get an easy-to-follow overview for planning dehumidifier projects.

It covers system design, dehumidifier selection & sizing, drying psychrometrics, energy saving and much more.

You may also be interested in...

Wind turbine dehumidification

Hammam, Caldarium and Rhassoul

Steam baths

Outdoor mist cooling systems

Dehumidifiers for ice prevention in cold store and freezers

Humidification & humidity control in semiconductor & PCB manufacturing

Insectary & insect breeding

Drying Rooms

Swimming pool dehumidification